| ONLINE PRODUCT BUILDER >>> |

Please select your options in the list below the diagram to configure your

Thermocouples

and request a quote.

Fast Order

Already have the module number? Enter them here with quantities and add directly to the cart!

Don't know which configuration to choose ? Please don't hesitate to contact us

You can also download our

Thermocouples

catalog if you prefer. |

| SINGLE PRODUCT PAGE |

Download this page from our thermocouples catalog to generate your product code. Download this page from our thermocouples catalog to generate your product code. |

| COMPLETE CATALOG |

Download our complete thermocouples catalog. (18.7 MB) Download our complete thermocouples catalog. (18.7 MB) |

|

| Product Name: |

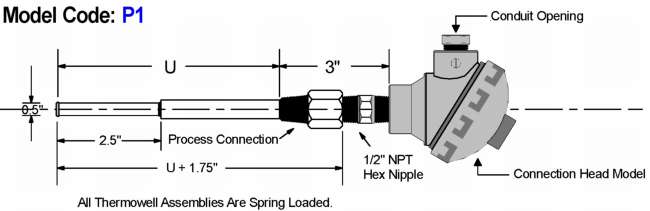

Standard Stepped Threaded Thermowell |

Application: |

Temperature Sensor For Mineral Insulated Industrial,

industrial processes, heavy duty and special applications, Heat Treating, Furnace, Oven,

power-generation |

| Calibration: |

TYPE J, TYPE K, TYPE T, TYPE E, TYPE N |

Operating temperature: |

-200 C to +1000 C Max |

Description:

Mineral Insulated Standard Stepped Threaded Thermowell Available in thermocouple types J, K, T, E and N.

The Threaded Fitting Thermocouple Thermowell Assembly is built for use in applications where facile removal of the spring loaded sensor is a required option without the need to turn off the system.

Thermowells are utilized to ensure temperature sensors used to monitor mechanical procedures while allowing accurate measurement. A thermowell comprises of a tube closed toward one side and mounted in the process stream. A temperature sensor is inserted in the open end of the tube, which is ordinarily in the

open air outside the procedure piping or vessel. The procedure fluid transfers heat to the thermowell wall, which in turn transfers warmth to the sensor. Since more mass is available, the reaction time of the sensor can be reduced. In any case, if the sensor fails it can easily be supplanted

without draining the vessel or piping. To acquire accurate temperature estimation the recommended thermowell immersion length is ten times the outside diameter of the tip.

The thermowell shields the instrument from the pressure, flow-induced powers and chemical effects of the process fluid. Normally a thermowell is made from metal bar stock bored to accept the temperature sensor with a NPT thread or flange for process mounting.

|